This is a custom cable and is non-cancellable and non-returnable.

Custom MTP® trunk cables including custom lengths, jacket colors and other options are available upon request. To find out more information, please call us or email us.

Description

MTP® Fiber Trunk Cable, Multimode 50/125 10 Gig OM3, 48 Strand, Plenum

These high speed multimode 50/125um OM3 MTP® trunk cables are terminated with MTP® fiber optic connectors on both ends with one connector for every 12 strands. The MTP® ("Multifiber Termination Push-on") connector is a multifiber connector developed by USConec that contains up to twelve optical fibers within a single ferrule.

Each one of the MTP® cables contain 12 fibers or 6 duplex channels in a connector smaller than most duplex connections in use today. MTP® fiber cables are designed as a high-performance version of the MPO style cable and will interconnect with MPO connectors.

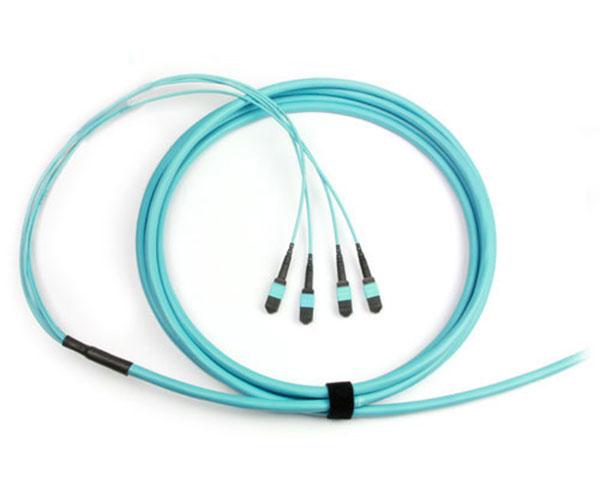

A 48 strand MTP trunk cable will have four 12 fiber MTP® connectors on each end. Below is an example.

Additional Information

MTP® High Density Cable

With up to 12x the density, industry experts agree that MTP® will eventually replace ST, SC, MTRJ, LC, FC and all other fiber connector types on the market today. Using MTP® connectors, a 1U rack mount patch cable can supply data for an entire 288-port switch. Combined with an MTP® cassette, this is a true plug-and-play solution.

MTP® vs. MPO

MTP® is the trademarked version of the generic MPO connector type, featuring significant advantages. Its removable housing makes the MTP® easier to rework than an MPO connector, allowing for gender changes and interferometric scanning.

The MTP® also has increased ferrule float which allows mated ferrules to remain in physical contact while connected. In contrast to the pins on an MPO connector, the MTP® has elliptical shaped guide pins to reduce wear on guide holes for the purpose of reducing debris that would cause additional loss through self contamination. Guidance is also improved.

Another advantage of the stainless steel pin design is its adherence to tight tolerances controlled during the manufacturing process. For post manufacture precision, a pin clip holds the pin guide in place. Other advantages of the pin clip is the elimination of lost pins and centering the spring force to eliminate damage caused by an un-centered spring.

Polarity Types

The polarity type determines which fibers connect from each end. With 12 fiber positions, these are the three types:

Method Type A MPO/MTP® Trunk Cables

also referred to as straight through, connects fiber 1 in the first cassette to fiber 1 in the second cassette, following this pattern through each of the 12 fiber positions—see table 1.0 below. One end is key up and the other end is in the key down position.

Table 1.0 | Polarity Method Type A

Method Type B MPO/MTP® Trunk Cables

also referred to as cross or flipped, connects fiber 1 in the first cassette to fiber 12 in the second cassette, following this pattern through each of the 12 fiber positions, with the last being 12-1—see table 1.1 below. Both ends are in the key up position.

Table 1.1 | Polarity Method Type B

Method Type-C MPO/MTP® Trunk Cables

also referred to as cross pair or rollover, connects fiber numbers in pairs, starting with 1-2 and 2-1 on one end, 11-12 and 12-11 on the other end—see table 1.2 below for all of the fiber pairings. One end is key up and the other end is in the key down position.

Table 1.2 | Polarity Method Type C